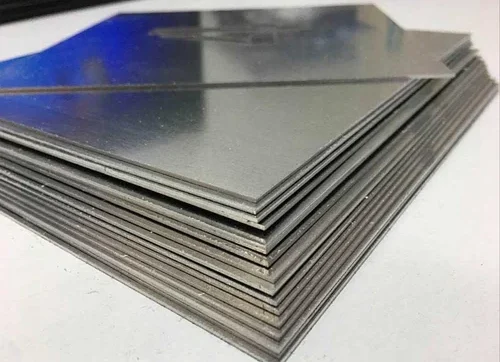

Incoloy Sheets

High-Temperature, Corrosion-Resistant Alloy Sheets for Demanding Industrial Applications

RSD offers premium-grade Incoloy Sheets, designed for durability in high-temperature and corrosive environments. Composed primarily of nickel, iron, and chromium with additional elements depending on the grade. Incoloy is engineered for structural stability and oxidation resistance in extreme industrial conditions.

From heat exchangers and furnace trays to power plant tubing and pollution control equipment, Incoloy Sheets deliver unmatched performance in industries where other materials degrade. Their metallurgical structure makes them suitable for continuous service at elevated temperatures without sacrificing strength or corrosion resistance.

Grades & Specifications

- Available Grades:

- Incoloy 800 (UNS N08800)

- Incoloy 800H / 800HT (high carbon variants)

- Incoloy 825 (UNS N08825)

- Thickness Range: 0.5 mm – 50 mm

- Width & Length: Custom cuts up to 2500 mm wide

- Standards: ASTM B409 (for 800 series), ASTM B424 (for 825)

- Finishes: No.1, 2B, hot-rolled annealed, pickled

Key Features & Benefits

Outstanding Oxidation & Carburization Resistance:

Incoloy resists surface scaling and degradation in high-temperature conditions, especially in furnace atmospheres, making it ideal for continuous heat exposure.

Strong Mechanical Properties at Elevated Temperatures:

Maintains tensile and rupture strength even when exposed to temperatures above 1000°C, especially in the 800H/800HT variants.

Corrosion Resistance in Acidic & Aqueous Media:

Incoloy 825, in particular, shows strong resistance to sulfuric acid, phosphoric acid, and seawater, enabling use in chemical and marine sectors.

Good Fabricability & Weldability:

Incoloy Sheets are easily formed and welded using standard techniques, with minimal risk of sensitization or cracking.

Common Applications

Incoloy Sheets are widely used in:

- Thermal Processing Equipment:

Furnace trays, baskets, hangers, and radiant tubes where heat resistance is critical. - Power Generation & Nuclear:

Steam generator tubing, superheaters, and heat exchangers in nuclear and fossil-fuel power plants. - Chemical & Petrochemical Industry:

Reactors, acid tanks, evaporators, and heat exchangers exposed to mixed chemical flows. - Marine Applications:

Incoloy 825 is used in seawater piping systems, offshore structural components, and desalination plants. - Pollution Control:

Stack liners, ductwork, and scrubbers in flue gas desulfurization units.

Why Choose RSD for Incoloy Sheets?

Mill-Certified Quality:

All Incoloy Sheets come with complete traceability, Mill Test Certificates (MTCs), chemical analysis reports, and compliance with international standards.

Custom Processing Capabilities:

We offer sheet cutting, edge preparation, surface finishing, and customized dimensions per your application.

Global Delivery Logistics:

With export-ready packaging and partnerships with major logistics providers, RSD ensures safe, on-time delivery across India and globally.

Industry-Specific Expertise:

We help you choose the ideal grade—800H for high-temperature strength, or 825 for acidic corrosion protection—based on your process conditions.

Industries We Serve

- Thermal Engineering & Heat Treatment

- Oil & Gas Refineries

- Chemical Processing Units

- Power & Energy Sector

- Marine and Offshore Engineering